what iron ore crusher for sinter fines

IRON ORE STEEL | McNally Sayaji

Basically Rod Mills (Grinding Mill)are used in Iron Ore beneficiation and in Pelletisation and Coke Crushing for preparation of Sinter Mix in Sintering Plants. Ball Mills (Grinding Mill) Ball Mills (Grinding Mill) are used for size reduction to microns and form part of grinding circuit in an Iron Ore Beneficiation/ Pelletisation Plant....

iron ore sinter concentrate pellet fines

Sintering of iron ore is a generic term which is used to describe the process whereby a sinter mix (raw mix or green mix) of iron ore fines, fluxes, fuel (coke breeze) and plant return fines (eg mill scale, blast furnace dust, and returned sinter fines etc) are converted into a particular form of . IRON ORE FINES lmalloyds...

iron ore sintering machine

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals....

ultra fines iron ore in sinter production

Sintering of iron ore is a generic term which is used to describe the process whereby a sinter mix (raw mix or green mix) of iron ore fines, fluxes, fuel (coke breeze) and plant return fines ( mill scale, blast furnace dust, and returned sinter fines etc.) are converted into a particular form of agglomerate....

Iron Ore Crusher Vs Iron Ore Fine

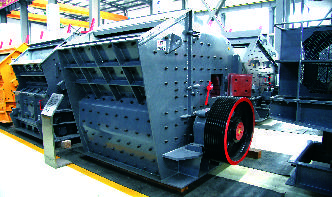

Our crushers are widely accepted across various industrial sectors like metallurgy, mining, building material, energy etc. Different types of Crusher for glass grade material – single and double toothed roll crushers, smooth double roll crushers, and sinter crushers or Iron ore crusher with less fines....

sintering iron ore process

Sintering of iron ore is a generic term which is used to describe the process whereby a sinter mix (raw mix or green mix) of iron ore fines, fluxes, fuel (coke breeze) and plant return fines ( mill scale, blast furnace dust, and returned sinter fines etc.) are converted into a particular form of agglomerate....

vibrating feeder sinter ore

A process for producing sintered ore with high reducibility by sintering a raw ..... 9, the numeral 9 is a sinter crusher, and 14 is a vibrating feeder. Read more Effective Beneficiation of Low Grade Iron Ore Through Jigging ......

iron ore fines size for sintering

iron ore fines size for sintering. grind size needed fpr iron ore sintering. Iron ore pellets and Pelletizing processes Pelletizing is a process that involves mixing ... Iron ore pellets and Pelletizing processes Pelletizing is a process that involves mixing ......

Iron ore – improving ore quality AusIMM Bulletin

Some iron ore companies are already marketing 'green' iron ore pellets, while others are only just starting to develop beneficiation processes for their production sites. For a highgrade iron ore deposit (ie greater than 62 per cent), a dry crushing and sizing process is sufficient to achieve the required product quality and size fraction as lump ore, sponge ore or sinter fines (MetalBulletin, 2014)....

process plant for iron ore sinter

The iron ore sintering process prepares fine iron the ores for the blast furnace process Sinter plants agglomerate iron ore fines with other fine materials at high temperature in a mix bed to create a product that can be used in a blast furnace Main feed into a sinter plant is base mix, which consists of iron ore, ....

chrome ore sintering process | Solution for ore mining

small sinter plant iron ore. Sinter Plant Wikipedia, the free encyclopedia Sinter plants agglomerate iron ore fines (dust) ... The final product, a sinter, is a small, irregular nodule ......

iron ore sinter concentrate pellet fines

iron ore sinter concentrate pellet fines msblegalin. Iron ore pellets | ispatgu Iron ore pellets Iron ore pellet is a type of agglomerated iron ore fines which has better tumbler index when compared with that of parent iron ore and can be used as a substitute of lump ore for the production of direct reduced iron (DRI) and in blast furnaces for the production of hot metal...

iron ore sintering process ppt

The purpose of the sinter plant is to process fine grained raw materials into a coarse grained iron ore sinter, ready to be charged to the blast furnace. Sintering of fine particles into a porous clinker – sinter – is necessary to improve the permeability of the burden, making reduction easier....

iron ore fines plants capacity" sinter india china ...

Nov 09, 2012· Iron Ore Processing,Crushing Screening,Grinding,Beneficiation .. Small capacity crushers have now . Since steel plants are switching over to sinter, iron ore fines are now .Iron Ore Fines/blue dust cannot be . »More detailed...

Iron ore sintering ScienceDirect

The sintering process begins with the preparation of a sinter mixture consisting of iron ore fines, fluxes, solid fuel (called bonding agents in Japan) such as coke breeze, and return fines from the sinter plant and blast furnace as well as recycled ferruginous materials ....

SAFETY GUIDELINES FOR IRON STEEL SECTOR MINISTRY .

mass itself. Iron ore fines, coke breeze, limestone and dolomite along with recycled metallurgical wastes are converted into agglomerated mass at the Sinter Plant, which forms 7080% of iron bearing charge in the Blast Furnace. This entire process of sinter making is associated with various hazards safety...

Iron ore grind size sinter Henan Mining Machinery Co., Ltd.

Are iron ore pellets better than sinter. sintering iron pellet Newest Crusher Grinding iron ore pellets vs sinter pakistan crusherstone crusher Gulin machine in iron ore processing plant iron ore pellets vs sinter iron ore fines of size less than 200 mesh iron ore pellets iron ore pellet is a type of agglomerated iron ore . ....

sintering of iron ore fines in steel plant

The Kaunisvaara Pellet Feed Northland Resources Iron ore fines fine iron ore with particle size of 1 – 6 mm, also called sinter feed .... for introduction of the fluxes and is good for recycling steel plant wastes....

pelletisation or sintering of iron ore

Iron ore pelletizing systems pelletisation or sintering of iron ore,Iron ore pelletizing systems. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make OF SIZE DISTRIBUTION AND WATER CONTENT ON ...processes for iron ore fines are pelletisation and sintering....

Ironprocess sintering of iron ores YouTube

Sep 30, 2012· In this way, lump or rubble ore (7 to 25 millimetres in size) is separated from the fines (less than 7 millimetres). If the lump ore is of the appropriate quality, it can be charged to the blast ......

Crusher Sinter Ore

American fine ore crusher . what iron ore crusher for sinter fines , sintering of iron ore fines Newest Crusher,, Sinter plants that are located in a steel plant recycle iron ore fines from the raw material, American Genealogy ....

what iron ore crusher for sinter fines

Indian Iron Ore Scenario : Low Grade Iron Ore what iron ore crusher for sinter fines, Wide reserves of iron ore is found in India which is the basic raw material for iron and by making sinter/ pellet using advance techniques of beneficiation involving gravity....

Process For The Pelletization of Iron Ore Fines

We have developed the Indigenous Technology for Iron Ore Pelletization Plant and . in Online production of Sponge Iron directly from Iron Ore Fines. This process . IRON ORE PELLETS – Henan Hongda Furnace Industrial Co.,LTD....